Views: 6 Author: Site Editor Publish Time: 2022-09-27 Origin: Site

Steps and precautions for electronic assembly.

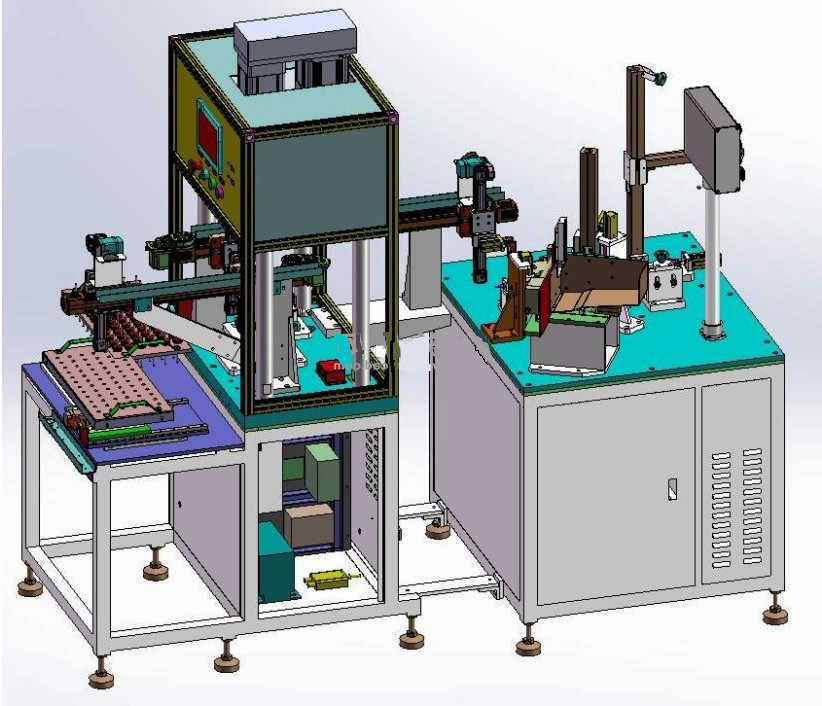

1. Automatic shaft feeding machine

Six station turntable is adopted, and one station is the rotor clamping area (grasping the motor rotor core), which can realize the automatic loading and unloading of rotors on the assembly line;

The third station is empty; The fourth station is the feeding and pressing station of the shaft, and the fifth and sixth stations are high-frequency heating stations. The rotary table is driven by the indexer motor, and the angle tolerance of repeated positioning is ± 0.1.

2. Automatic circlip machine

Touch screen design, friendly user interface, easy to operate and powerful.

Push feeding is adopted for pressing, and air cylinder is used for punching and displacement to ensure the stability of pressing, no damage to the shaft and the accuracy of the position.

The translation conveying mechanism is used for equipment conveying to connect with the automatic assembly line to maintain the smoothness of the whole line.

3. Automatic bearing feeder

The cylinder is used for pushing and feeding during crimping, and the servo motor is used to drive the crimping. The stability of crimping must be ensured. It is able to adjust and control the crimping height, identify the crimping quality every time, and give an audible alarm to the operator once there is a problem in the crimping.

Moving conveying structure of reclaiming station; The equipment shall be transported together with the product tooling, and the tooling shall be connected with the automatic assembly line in the form of overall transportation

4. Automatic nut feeder

Vibrating disc feeding and mechanical hand suction cup feeding are adopted

5. Magnetizing machine

The rotor feeding and unloading are driven by a servo motor to achieve accurate positioning.

Closed operation to ensure safety.

The reclaiming station is servo driven by a long manipulator, and the finished products are placed on the return line of the conveyor line.

6. Press

Manual loading shall be adopted for crimping, and the cylinder shall be used for stamping and displacement. The stability of crimping must be ensured. It is able to adjust and control the crimping height, identify the crimping quality every time, and send visual and audible alarm to the operator once there is a problem in crimping.

7. Automatic front cover feeding and crimping machine

Six station rotary table is adopted, and the rotary table is driven by the indexer motor, and the repeated positioning angle tolerance is ± 0.1.

After pressing and feeding, press and shift with servo motor drive to ensure the stability of crimping. The crimping height can be adjusted and controlled.

8. Automatic screw driver

Closed operation to ensure safety,.

Servo control is adopted for screwing, and the torque sensor precisely controls the depth of screwing in. The stability of the motor must be ensured.

Xiaomi equipment manufacturing motor assembly platform

Whether the bearing is assembled correctly affects the accuracy, service life and performance. Therefore, the way of bearing assembly is very important. Today, Qingdao Xiaomi Equipment Manufacturing Co., Ltd. shares the correct way of bearing installation, error demonstration, and precautions in bearing use.

Bearing installation shall be carried out in a dry and dust-free area as far as possible, and shall be far away from equipment that will produce metal chips and dust. When it is necessary to install in a complex environment, the pollution should be minimized. When installing bearings, mechanical, heating or hydraulic methods should be selected according to the type and size. The installation methods of cylindrical bearings include: cold installation and hot installation. Generally, it is impossible to assemble larger bearings without heating the bearings or bearing seats, because the larger the size, the greater the force required for installation. The temperature difference between the bearing ring and the shaft or bearing seat required for hot installation mainly depends on the interference amount and the diameter of the bearing fitting place. The heating temperature of open bearing shall not exceed 120 ℃. It is not recommended to heat the bearing with seal and dust cover to more than 80 ℃ (ensure that the temperature does not exceed the allowable temperature of seal and grease).

When heating the bearing, it should be heated evenly, and no local overheating is allowed.

Precautions for bearing use:

Rolling bearings are precision components, and their use must be carried out with corresponding caution. No matter how high performance bearings are used, they will not achieve the expected high performance if improperly used. Precautions for the use of bearings are as follows:

1. Keep the bearing and its surroundings clean

Even if invisible tiny dust enters the bearing, it will also increase the wear, vibration and noise of the bearing. The bearing and its surrounding accessories shall be kept clean, especially dust and dirt. Tools and working environment must also be kept clean.

2. Be careful when using and installing

It is not allowed to punch forcefully, strike the bearing directly with a hammer, or transmit pressure through rolling elements.

3. Use proper and accurate installation tools

Try to use special tools, and try to avoid using cloth and short fibers.

4. Prevent bearing corrosion

When the bearing is taken directly by hand, the sweat on the hand should be fully washed and coated with high-quality mineral oil before operation. Pay special attention to rust prevention in rainy season and summer. However, under some special operating conditions, the bearing can obtain a longer life than the traditional calculation, especially under light load. These special operating conditions are surface damage that may be caused when rolling surfaces (rails and rolling elements) are effectively separated and restricted by a lubricating oil film. In fact, under ideal conditions, the so-called permanent bearing life is possible.

Bearing assembly equipment platform