| Availability: | |

|---|---|

| Quantity: | |

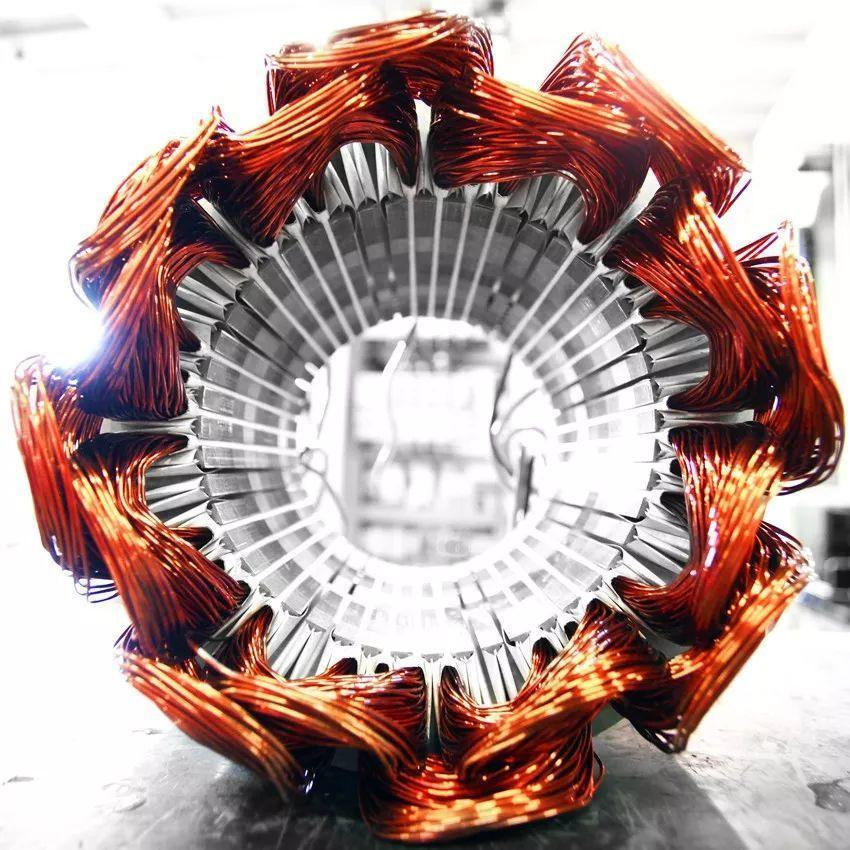

Automatic stator production line

This stator production line is suitable for brushless motor stator production.The stator manufacturing line consists of paper inserting machine, end insulation board inserting machine, needle winding machine, stator tester, tracing system and belt conveyor.

Operator fill material, each process is completed automatically, automatically transfer the stator to next process. The winding processing parameter can be set and saved on HMI, and can be called out at any time.

It features High intelligent, high automation, high efficiency and low noise.This Full automatic motor stator manufacturing production line has remote diagnosis function.This fully automatic stator winding is suitable for the production of single-phase motor stators, including fan motors, water pump motors, industrial motors, NEMA motors, etc... All processes are completed automatically.

It is fast, efficient, high slot filling, easy to set up, user-friendly programming and tool flexibility, which is conducive to the consistency of motor quality.

In order to avoid damaging the stator coils, the coil insertion machine uses dual power supplies to drive the coils to meet the requirements of producing stators with high slot filling rates.

Main features of stator wire

1. The stator production line consists of two parts, a conveyor and a stand-alone machine. The transmission and conversion process of the stator is completed by the robot arm between the conveyor and the independent machine. The action of the machine is completed by the handshake control between the conveyor belt and the independent machine.

2. Each workstation of the stator wire has an independent control function and can work independently.

3. The conveyor is equipped with an independent control system. It can lift, position and stop the stator.

4. With automatic positioning function, the stator can be loaded and unloaded in the paper feeding station.

5. The mechanical robot is used to connect the paper insertion station and the automatic coil insertion station during the production process. It is stable during running. The stator position of the robot arm is more accurate.

6. The robot arm is used to connect the forming station and the conveyor during production.

7. Use robotic arm to connect shoelace station and conveyor during production. The shoelace and knotting process can be done automatically.

8. This stator wire can automatically test the stator, and then judge whether the stator is qualified or unqualified for the next process.

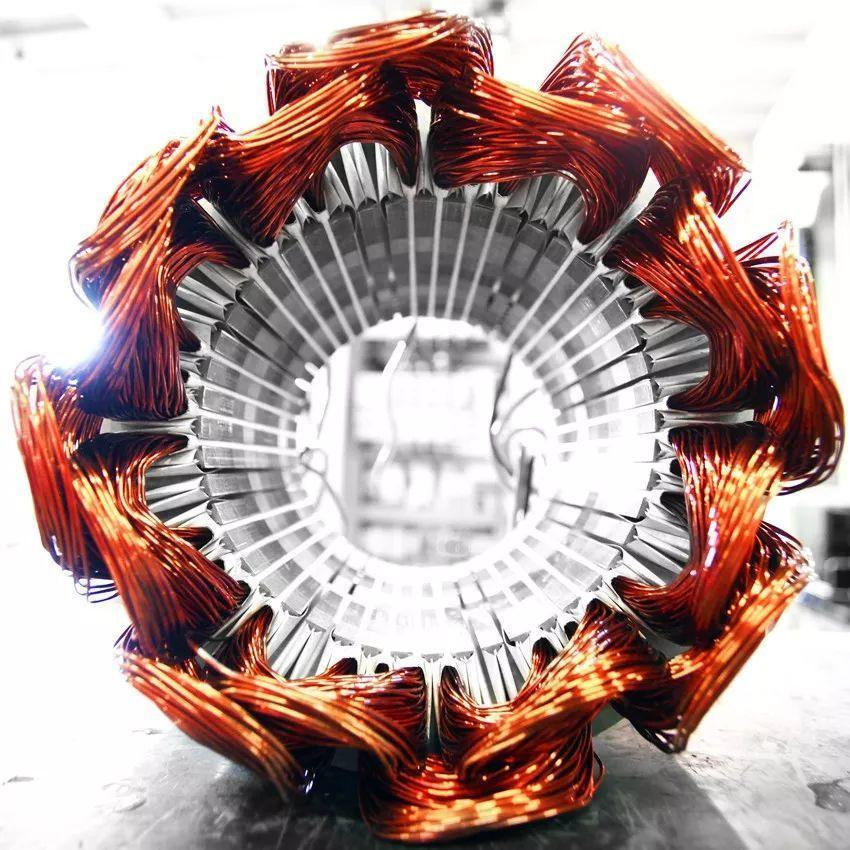

Automatic stator production line

This stator production line is suitable for brushless motor stator production.The stator manufacturing line consists of paper inserting machine, end insulation board inserting machine, needle winding machine, stator tester, tracing system and belt conveyor.

Operator fill material, each process is completed automatically, automatically transfer the stator to next process. The winding processing parameter can be set and saved on HMI, and can be called out at any time.

It features High intelligent, high automation, high efficiency and low noise.This Full automatic motor stator manufacturing production line has remote diagnosis function.This fully automatic stator winding is suitable for the production of single-phase motor stators, including fan motors, water pump motors, industrial motors, NEMA motors, etc... All processes are completed automatically.

It is fast, efficient, high slot filling, easy to set up, user-friendly programming and tool flexibility, which is conducive to the consistency of motor quality.

In order to avoid damaging the stator coils, the coil insertion machine uses dual power supplies to drive the coils to meet the requirements of producing stators with high slot filling rates.

Main features of stator wire

1. The stator production line consists of two parts, a conveyor and a stand-alone machine. The transmission and conversion process of the stator is completed by the robot arm between the conveyor and the independent machine. The action of the machine is completed by the handshake control between the conveyor belt and the independent machine.

2. Each workstation of the stator wire has an independent control function and can work independently.

3. The conveyor is equipped with an independent control system. It can lift, position and stop the stator.

4. With automatic positioning function, the stator can be loaded and unloaded in the paper feeding station.

5. The mechanical robot is used to connect the paper insertion station and the automatic coil insertion station during the production process. It is stable during running. The stator position of the robot arm is more accurate.

6. The robot arm is used to connect the forming station and the conveyor during production.

7. Use robotic arm to connect shoelace station and conveyor during production. The shoelace and knotting process can be done automatically.

8. This stator wire can automatically test the stator, and then judge whether the stator is qualified or unqualified for the next process.